Technological possibilities:

3D, spatial machining; laser cutting and welding.

Short description of the equipment:

The device is a 5 kW CO2 gas laser with 5-axis CNC beam guidance for 3D spatial machining (cutting, welding).

Technological possibilities:

3D, spatial machining; laser cutting and welding.

Short description of the equipment:

The device is a 5 kW CO2 gas laser with 5-axis CNC beam guidance for 3D spatial machining (cutting, welding).

Technological possibilities:

3D, spatial laser machining; welding, surface modification, surface hardening, powder coating (LSA).

Short description of the equipment:

The device is a 2.7 kW Nd: YAG solid state laser with fiberglass beam guidance. The beam is controlled by a 7-axis robot, and an external rotary axis is available to move the workpieces. A scanner head can be used for surface treatment technologies (surface modification, surface hardening, powder coating).

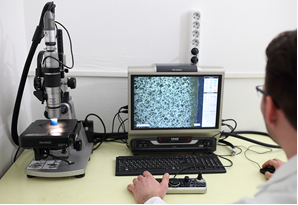

Technological possibilities:

investigation of the microstructure and surface properties (hardness, morphology) of metals.

Short description of devices:

Water-cooled diamond disk cutters can cut samples above 60 HRC. Depending on the number of samples, it is possible to use machine-assisted or manual embedding. The samples can be grinded and polished manually, or with larger numbers with an automatic grinding and polishing equipment. Microscopic images can be taken using a digital optical microscope, capable of producing a 3-dimensional image from Keyence. The hardness of the sample phases can also be measured with the Leica Micro Vickers hardness tester. A hardness map can be created with an ultrasonic hardness tester driven by a high-precision stepper motor.

Sándor TAKÁCS – Head of Department, Department of Production Development

Address: H-1116 Budapest, Kondorfa u. 1.

Cell: +36-70/515-7166

E-mail: sandor.takacs@bayzoltan.hu

1.) Rofin CO2 Slab radiation source

Technological possibilities:

deep-seam welding of automotive parts

laser cutting of metal parts

Short description of the equipment: 4.5 kW CO2 laser source with two optical pathways. Deep-seam welding can be performed on the first pathway. The parts are fed in a belt system on a production line suitable for circular symmetrical welding. The second pathway can be used for laser cutting of special automotive parts. Both tools are the company’s own development.

2.) SCANLAB laser

Technological possibilities:

laser cleaning

engraving, surface treatment

Short description of the equipment: The 40 W fiber laser has a scanner head. It removes dirt from complex parts without damaging or deforming the surface.

3.) ULTRASONIC MATERIAL TESTING (UT):

Ultrasonic material testing is used to determine the anomalies in the welds of the parts we manufacture.

Tibor VÁLLAJI – Head of Laboratory, Laser Technology Laboratory, Department of Production

Address: H-1116 Budapest, Kondorfa u. 1.

Cell: +36 30/442-1418

E-mail: tibor.vallaji@bayzoltan.hu